Global 3D Printing Materials Market for Aerospace Industry, Forecast to 2024

Global 3D Printing Materials Market for Aerospace Industry, Forecast to 2024

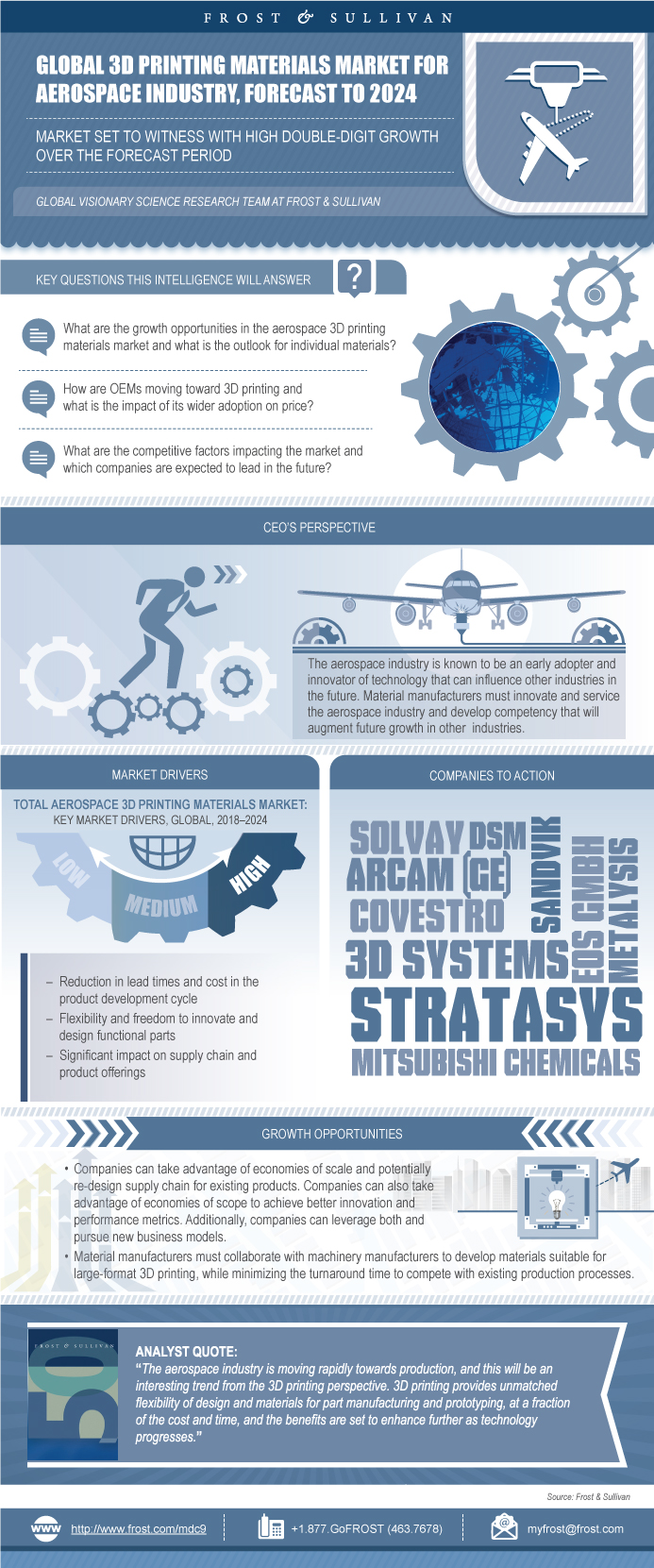

Market Set to Witness Exemplary Growth with High Double-digit Growth Over the Forecast Period

15-May-2018

Global

$4,950.00

Special Price $3,712.50 save 25 %

Description

This research service analyzes the global 3D printing materials market for the aerospace industry. The main segments covered by product type are plastic powders, plastic filaments, and metal powders. Plastic powders are further sub-segmented into polyamide, TPU, PEEK, and others. Plastic filaments are sub-segmented into PEI, ABS, polycarbonate, and others. Metals are sub-segmented into titanium, inconel, aluminum, and others. In terms of applications, the market has been fragmented into rapid prototyping, tooling, and production. End-user segments are represented by aircraft and spacecraft. Functional segments are represented by body & interiors, jigs & tools, and engine. Major market drivers and restraints, regional demand outlooks, application growth trends, and product trends are also discussed. Unit shipment and revenue forecasts have been provided for each segment from 2014 to 2024. Competitive structure and market share data have been provided at the top level. The competitive environment has been covered for each segment. The base year is 2017 and the forecast period ends at 2024.

Mega Trends: Functionality & performance, minimization of carbon footprint, and globalization of manufacturing services are the key Mega Trends that impact the aerospace additive manufacturing industry. Weight optimization without compromising on the safety and functionality is an area of high interest and research for all OEMs and parts manufacturers alike. Considerably lower material wastage results in lower carbon footprint. Influencing Factors: Unlike most industries, production is the largest application for 3D printing in the aerospace industry. Design freedom, quick turnaround time, and ability to produce on demand are the few factors that exert a major influence on the market penetration of 3D printing technology in the aerospace industry. Lack of clear guidelines and high capital involvement restrain the wider adoption of the technology in the industry. However, as a large number of success stories evolve in the industry, the acceptance of 3D printing is projected to increase.

Regional Trends: North America and Europe have traditionally led the aerospace 3D printing materials market in terms of demand and revenue due to the high R&D and presence of leading aircraft manufacturers, as well as system manufacturers. North America is set to be the most attractive region over the forecast period and lead regional demand in 2024. North America will be followed by Europe in terms of demand as well as revenue The Asia-Pacific region is a nascent market at present, with substantial growth potential. However, the cost-sensitive nature of the market restrains its potential in the present market condition.

RESEARCH: INFOGRAPHIC

This infographic presents a brief overview of the research, and highlights the key topics discussed in it.Click image to view it in full size

Table of Contents

Key Findings

Strategic Factsheet

Market Engineering Measurements

CEO’s Perspective

CEO’s Perspective (continued)

Market Definitions and Overview

Market Definitions and Overview (continued)

Key Questions this Study will Answer

Market Segmentation

Market Segmentation (continued)

Market Segmentation (continued)

AM Process Flow

Significance of AM

Comparative Study of Aerospace Manufacturing

Comparative Study of Aerospace Manufacturing (continued)

Impact on Manufacturing

Impact on Manufacturing (continued)

Mega Trend Impact on Aerospace 3D Printing Materials Market

Mega Trend Impact on Aerospace 3D Printing Materials Market (continued)

Opportunities for Materials—Main Technologies and Materials

Global Industrial 3D Printing Systems Market Share

Value Chain

Value Chain Discussion

Market Drivers

Drivers Explained

Drivers Explained (continued)

Drivers Explained (continued)

Drivers Explained (continued)

Market Restraints

Restraints Explained

Restraints Explained (continued)

Restraints Explained (continued)

Restraints Explained (continued)

Market Engineering Measurements

Forecast Assumptions

Unit Shipment and Revenue Forecast

Unit Shipment and Revenue Forecast Discussion

Percent Unit Shipment Forecast by Region

Unit Shipment Forecast by Region

Unit Shipment Forecast Discussion by Region

Percent Revenue Forecast by Region

Revenue Forecast by Region

Revenue Forecast Discussion by Region

Percent Unit Shipment Forecast by Product Type

Percent Revenue Forecast by Product Type

Percent Unit Shipment Forecast Discussion by Product Type

Percent Revenue Forecast Discussion by Product Type

Percent Unit Shipment Forecast by Applications

Percent Revenue Forecast by Applications

Percent Unit Shipment and Revenue Forecast Discussion by Applications

Percent Unit Shipment and Revenue Forecast Discussion by Applications (continued)

Percent Unit Shipment Forecast by Functions

Percent Revenue Forecast by Functions

Percent Unit Shipment and Revenue Forecast Discussion by Functions

Percent Unit Shipment and Revenue Forecast Discussion by Functions (continued)

Comparative Analysis of Material Segments

Future Outlook of 3D Printing by Applications

Percent Unit Shipment and Revenue Forecast by End User

Percent Unit Shipment and Revenue Forecast Discussion by End User

3D Printing Materials Market Share

Company—Stratasys Ltd.

Company—3D Systems Corp.

Company—EOS GmbH

Competitive Factors and Assessment

Competitive Factors and Assessment (continued)

Competitive Factors and Assessment (continued)

Product Matrix—Major Material Companies

Product Matrix—Major Material Companies (continued)

Product Matrix—Major Material Companies (continued)

Competitive Environment

Growth Opportunity 1—Leverage Price–Performance Trade-off to Enhance Market Penetration

Growth Opportunity 2—Focus on Catering to Different Requirements Within the Industry

Growth Opportunity 3—Emphasis on Value-added Service and Partnerships as Customer Acquisition Policy

Strategic Imperatives for Success and Growth

Key Findings

Market Engineering Measurements

Unit Shipment and Revenue Forecast

Unit Shipment and Revenue Forecast Discussion

Percent Unit Shipment Forecast by Product

Percent Revenue Forecast by Product

Percent Unit Shipment and Revenue Forecast Discussion by Product

Percent Unit Shipment and Revenue Forecast Discussion by Product (continued)

Key Findings

Market Engineering Measurements

Unit Shipment and Revenue Forecast

Unit Shipment and Revenue Forecast Discussion

Percent Unit Shipment Forecast by Product

Percent Revenue Forecast by Product

Percent Unit Shipment and Revenue Forecast Discussion by Product

Percent Unit Shipment and Revenue Forecast Discussion by Product (continued)

Key Findings

Market Engineering Measurements

Unit Shipment and Revenue Forecast

Unit Shipment and Revenue Forecast Discussion

Percent Unit Shipment by Product

Percent Revenue Forecast by Product

Percent Unit Shipment and Revenue Forecast Discussion by Product

The Last Word—3 Big Predictions

Legal Disclaimer

List of Exhibits

List of Exhibits (continued)

List of Exhibits (continued)

List of Exhibits (continued)

List of Exhibits (continued)

Market Engineering Methodology

Partial List of Companies Interviewed

List of Abbreviations and Acronyms

List of Abbreviations and Acronyms (continued)

Popular Topics

| No Index | No |

|---|---|

| Podcast | No |

| Author | Sayan Mukherjee |

| Industries | Chemicals and Materials |

| WIP Number | MDC9-01-00-00-00 |

| Is Prebook | No |

| GPS Codes | 9100-A2,9595,9869-A2 |

USD

USD GBP

GBP CNY

CNY EUR

EUR INR

INR JPY

JPY MYR

MYR ZAR

ZAR KRW

KRW THB

THB